Integration with ContiPressureCheck™

Reduce your overall operating costs by controlling tire pressure.

Your fleet’s tires literally support all the activity of your vehicles. No wonder then that the conditions in which they run have such a big impact on costs and safety.

Now, with Frotcom, you can follow up closely on these conditions, namely by controlling pressure and temperature. Not only do you detect and even anticipate tire failures, but you can also improve the total mileage run on each tire, by keeping tire pressure within the recommended interval.

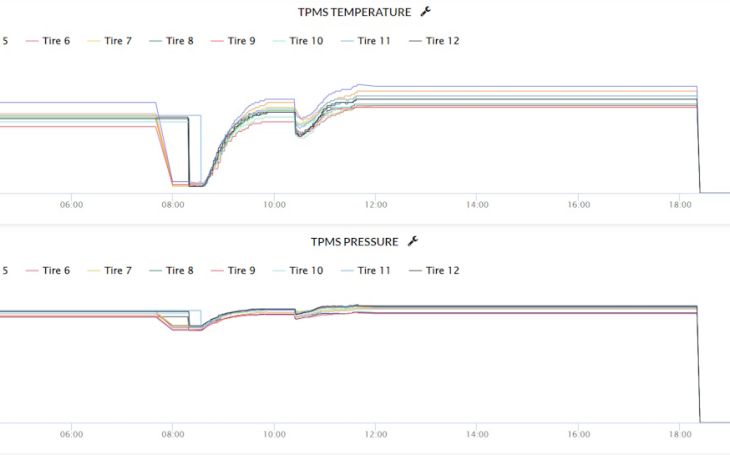

Once connected to Continental’s ContiPressureCheck™ tire monitoring system (TPMS) with the ignition on, Frotcom allows you to monitor the pressure and temperature in each individual tire.

You can define the pressure and temperature limits for each vehicle. If Frotcom detects an out-of-bounds situation, an alert will be generated, which can be sent to the corresponding driver and anyone else in the organization.

Because underinflated tires can lead to high operating costs*, all tires should have their inflation pressure kept in the recommended interval. However, monitoring tire pressures does not always happen as frequently as it should.

By monitoring your tires on a permanent basis, even while traveling, you will lower your operating costs and minimize the risk of tire failure.

*According to Continental, you can actively reduce operating costs by up to EUR 1,500 per vehicle a year. This calculation is based on a 4 x 2 tractor with a three-axle semi-trailer, driving 140,000 km per year (assumed price of diesel: 1 € / L), and including an estimated cost of EUR 700, also per year, for one tire-related breakdown incident.

Frotcom’s integration with Continental’s ContiPressureCheck™ tire monitoring system (TPMS) uses the following:

1. Tire sensors

Each tire is fitted with a battery-powered wireless tire sensor. The sensors are mounted on the tire inner liner, inside a rubber housing. When the ignition is on, they continuously measure the tire pressure and temperature.

2. Central communication unit

All sensors communicate wirelessly with a central unit. This unit collects information from all sensors, regarding pressure, temperature, and battery status.

3. Frotcom tracking device

Frotcom’s tracking device appends the tire data collected to other data being sent in real-time to Frotcom’s data center (GPS data, CANBus, data, etc.)

4. Battery status

In case Frotcom detects that the battery fitted in a sensor is low, it will generate the corresponding alert, so that the sensor can be substituted.

5. Data processing

The tire-related data is processed in Frotcom’s data center and compared to the prescribed intervals. If the pressure or temperature falls outside those intervals, alerts are generated. Frotcom can also automatically characterize pressure falling as being slow leaking or fast leaking.

6. Receiving an alert

Alerts are sent to the drivers, for instance by using the onboard Driver app. Hence, drivers can react accordingly and correct the problem in due time.

7. Semitrailers

The system is able to acknowledge cases in which trucks (the tractor heads) are coupled with semitrailers equipped with tire sensors. It will automatically recognize the new semitrailer and report the pressure and temperature of its tires.

Main features

- Automatic monitoring of tire conditions: pressure and temperature

- Alerts are sent to drivers and other people in the organization, so that situations can be corrected immediately

- Detection of low battery (in sensors)

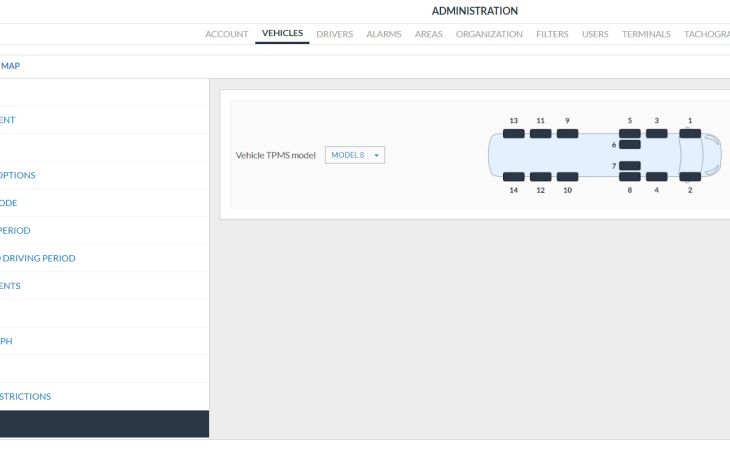

- Multiple layouts for different vehicle models and a combination of truck and semitrailer, to a maximum of 24 tires. It is suitable for tractors, trailers, tractor/trailer combinations, as well as buses and coaches

- Wireless communication from sensors to the Central communication unit.

Benefits

By driving with the correct air pressure, you reduce fuel consumption and the corresponding cost.

Permanent monitoring prevents tire-related breakdowns that can lead to vehicle downtimes, job delays, and, worse than that, accidents.

By running your tires at the recommended conditions, you increase the mileage for each tire and maintain the value of the tire casing and, thus, its retreadability.

By travelling at the correct inflation pressure, your vehicles not only lower fuel consumption and reduce tire wear, they also decrease CO2 emissions and consequently protect the environment.

Because tire pressure monitoring is now done automatically, you do not need to have your drivers frequently checking it. Their time can be better spent on other activities.