If you already have route planning software that works well for your company, that’s great! You just need to ensure that information is sent to your drivers and communicated to Frotcom’s fleet management software using the available API (application programming interface) so that Frotcom can monitor the execution of planned jobs and provide valuable insights for future planning.

If you still lack route planning software, the size of your fleet, and the complexity of its operations already require such planning, contact us. We recommend route planning software that fully integrates with Frotcom, ensuring the best coordination between planning and execution.

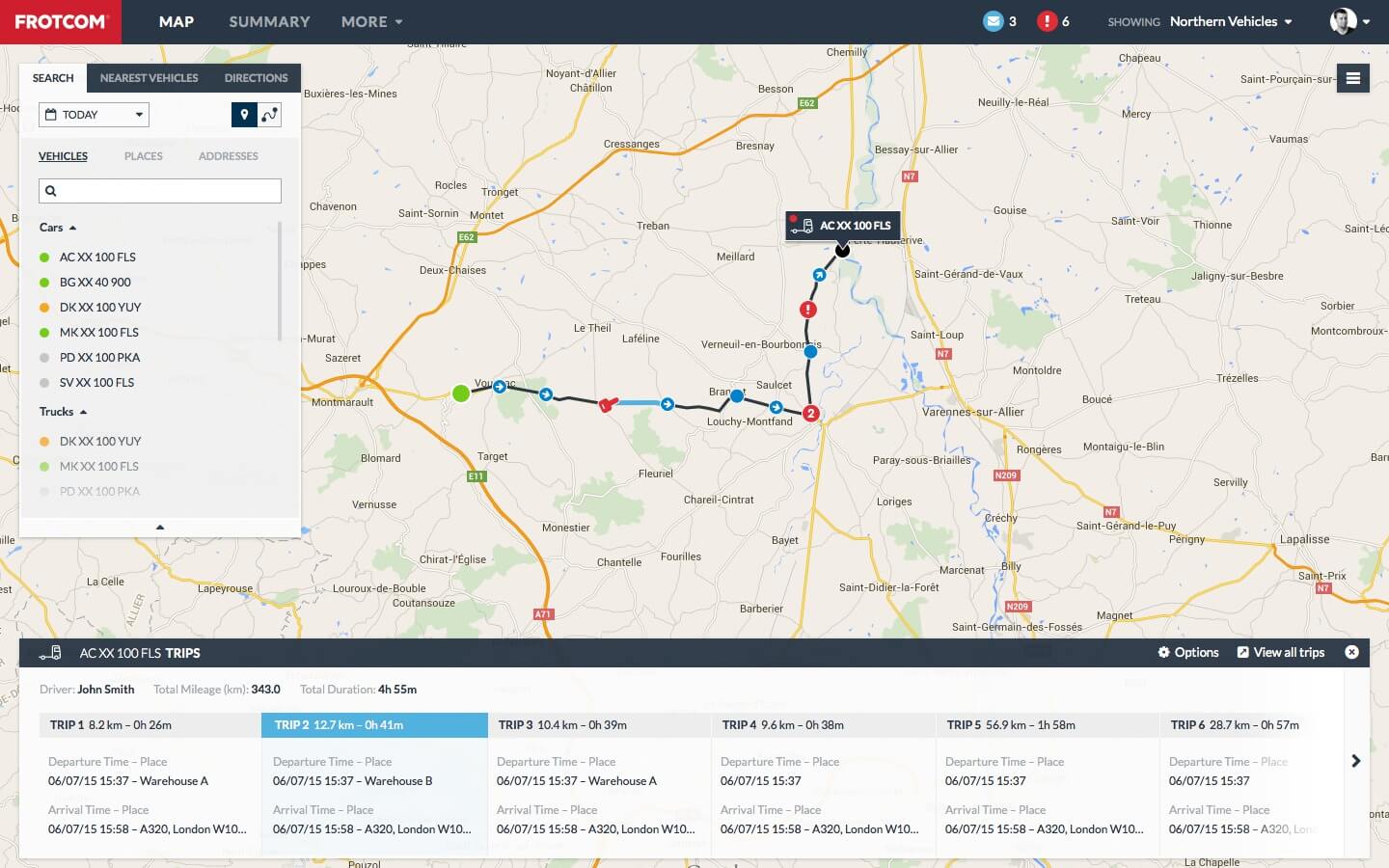

On the other hand, if your company’s operations do not yet require full route planning software, Frotcom still equips your fleet with powerful tools to increase fleet productivity. For instance, you can easily identify and assign the nearest available vehicle for a new service, considering the location and the driver’s remaining driving time. All monitored through Frotcom’s compliance and workforce management features.

Imagine being able to assign tasks to your drivers and communicate with them in real-time, no matter where they are. When you create a new job, the system sends instructions to the drivers' mobile devices, allowing them to immediately see what’s expected. Throughout the day, they follow their schedule, update their status, and ensure that nothing falls through the cracks.

At the same time, each driver keeps a digital record of their work activities, from start times and stops to completed services. This eliminates the need for manual logs, simplifies reporting, and ensures a clear and accurate view of daily operations.

Frotcom features work together to help you choose the correct driver and vehicle for every job, improving efficiency and ensuring compliance.